- Home

- Brand

- Manufacturer

- Marque

- Module

- Product Type

- Type

- Brake Calipers (3)

- Chain (7)

- Complete Seat (3)

- Echappement (6)

- Enduro (6)

- Engine Oil (3)

- Etriers De Frein (5)

- Exhaust (9)

- Ignition Coil (4)

- Kit Chaine & Pignon (3)

- Kit Chaîne (9)

- Luggage Rack (6)

- Miscellaneous (7)

- Radiateur (3)

- Radiator (9)

- Road Bikes (5)

- Silencieux (4)

- Transmission Kit (3)

- Various (4)

- Vélos De Route (26)

- Other (3321)

Set Transmission Silent JMT 525X216-49GOR for Honda 650 XRV Africa Twin 1988-19

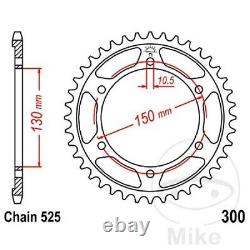

The production of JT Sprockets is today the largest and most modern sprocket and pinion production plant in the world, equipped among other things with the latest generation of CNC production machines. JT Sprockets manufactures the complete range of gears and sprockets for the spare parts market and original equipment.

Each sprocket and chain goes through 25 production steps and is then subjected to more than ten individual quality controls for successful production. JT Sprockets has done it right: for turning, milling, and drilling! This is the only way to achieve the best quality with the lowest tolerances and the best tooth profile. After the subsequent heat treatment, each component is manually checked - just like l.